Lotus Fibre is specialised in manufacturing of excellent quality FRP Motor Canopy, Frp Intrumentation Canopy, FRP Motor Canopies, Motor protection Shell Canopies, Motor Canopy. One of the leading Exporter, Supplier & Manufacturer in Mumbai India of FRP Motor Canopies, Our FRP Motor canopy and FRP Instrumentation Canopy is extensively used in various industries for protecting the motor and intrumentation from weather etc. These frp motor canopies which is used for protecting various motors and instrumentation are manufactured using best quality frp material and by team of experts. The finished product of FRP Motor Canopy, Frp Intrumentation Canopy, FRP Motor Canopies goes through several parameters of quality check in line with industry standards and norms.

The necessity to protect the equipment, needs no emphasis. The daily failures due to one reason or the other is reminding us always. A little money extra spent on the protective means like frp motor canopies, is worth, than facing the breakdown and failures i.e. PRODUCTION LOSS. The motors are invariably subjected to abnormal circumstances (other than the designed parameters) such as

FRP Canopy Nature Of Work :

Installed Directly Under Sun / Rain

Installed In Dusty Atmosphere

Installed In The Vicinity Of Flying Objects (E.G. Waste Paper, Clothes, Leaves Etc.)

FRP Motor Canopies Accidental Conditions :

Hit by falling object

Excessive heating due to fire or heat in the vicinity.

Splash of oil / acid / corrosive substances

The motors should be protected from abnormal eventualities and should be guarded to minimize the risk of damages.

Products:

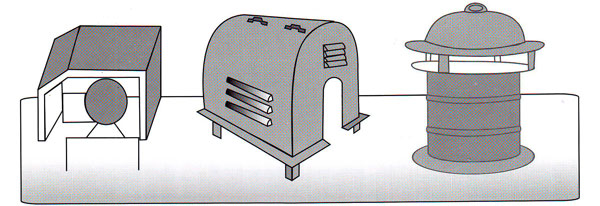

To protect the equipment FRP MOTOR PROTECTION SHELL is suggested, which is a cover made of FRP ( hand lapping process)

WHY FRP Motor Canopy for protection?

Because FRP is

Resistant To Corrosive Environment Of Coastal Areas /

Resistant To Corrosive Environment Of Coastal Areas /

Chemical Plants / Refineries

Mechanically Strong

No Water Absorption

Highly Insulating Material

U. V. Stabilised

Aesthetic Looks

Maintenance Free

Lightweight

Excellent Weatherability

The salient feature are :

FRP Motor Canopies and FRP Instrumentation Canopy Shape and Size :

The size of the FRP MOTOR PROTECTION SHELL CANOPY is based on the physical dimensions of the motor cover it is so selected that a uniform clearance of at least 50mm is maintained on all sides with respect to the motor body for the purpose of:

FRP INSTRUMENTATION CANOPY Should Cover The Motor Fully To Protect From

FRP Motor Protection Shell - Canopies Specification :

| No. | Parameters | Specifications |

|---|---|---|

1.

|

Material Of Construction | FRP |

2.

|

Type Of Resin | ISO - Phthalic / Gen Purpose |

3.

|

Glass Fibre | CSM OF 450GMS |

4.

|

Shape & Size | As Per motor Size |

5.

|

Colour | D. A. Grey |

6. |

Thickness | 3 to 5 mm |

7. |

Louvers | Yes |

8. |

Handles | Yes |

9. |

Finish | Outside Smooth Finish |

10. |

Stiffeners | Yes (in strip form by changing material orientation) |

11. |

Supporting | As Required At Site By Frp Angles / Channels |

12. |

Corrosion Resistivity | Yes |

13. |

Stability From U. V. Rays | Yes |

14. |

Moulding Process | Hand Lay - Up |

15. |

Flammability | Low Flammability as per IS - 6746 |

16. |

Glass Contents | 30 to 33% |

17. |

Oxygen Index | 30+ |

18. |

Flame Spread Index | 14 to 15 |

19. |

Antistatic | Yes ( If Required ) |

The FRP Motor protection shell is special designed by considering the general site conditions, the mounting arrangement The height of FRP Instrumentation Protection Shell Angles is adjusted according to the required parameters such as height of the motor above the foundation, rail mounted, flange mounted, resting directly over the foundation etc.

Precaution while Installing FRP Motor Canopy and FRP Instrumentation Motor Canopy - Motor Protection Shell:-

The FRP MOTOR PROTECTION SHELL should not significantly restrict air (Ventilation) Passage as such condition will lead to the burning of the motor (IT IS NOT SUPPOSED TO HAVE BOX LIKE SITUATION)